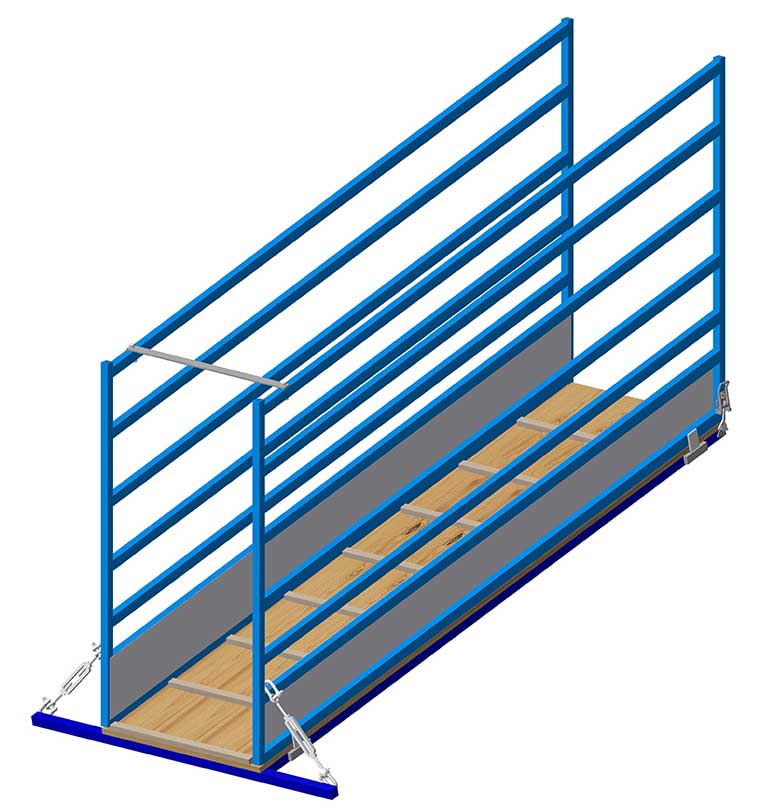

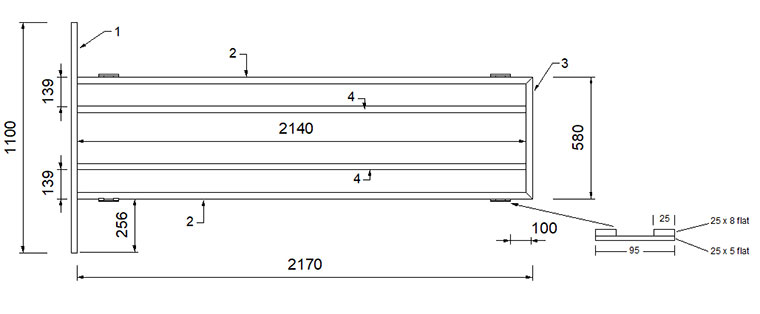

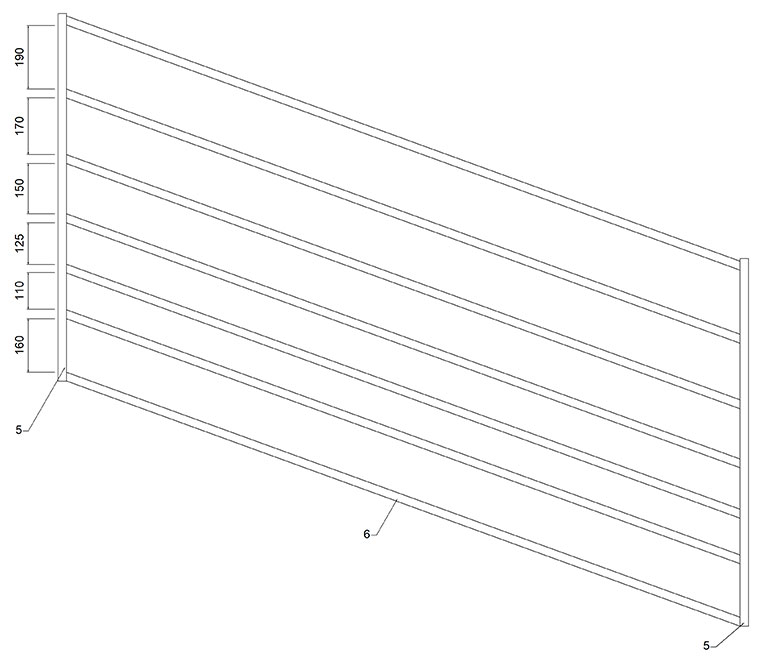

This 2.2 metre portable loading ramp is suitable for loading or unloading either sheep or goats. It can be transported easily as it breaks down into 3 separate parts.

The steel shown in the cutting list is only a guide as you may have other material already available that you can use.

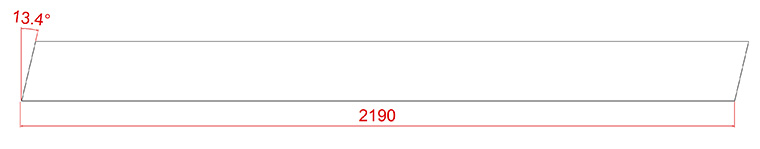

Note: If using timber for the floor, it is best to check the width of the timber you are going to use before cutting the angle for the floor to length to eliminate the need to rip the boards to fit.