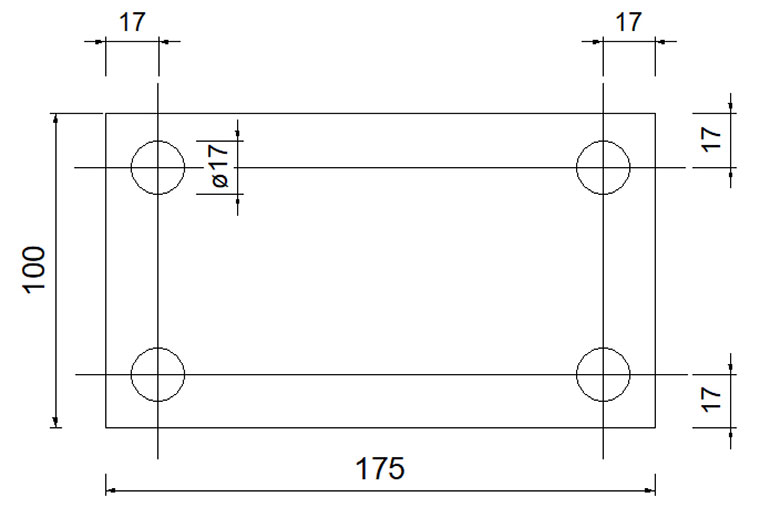

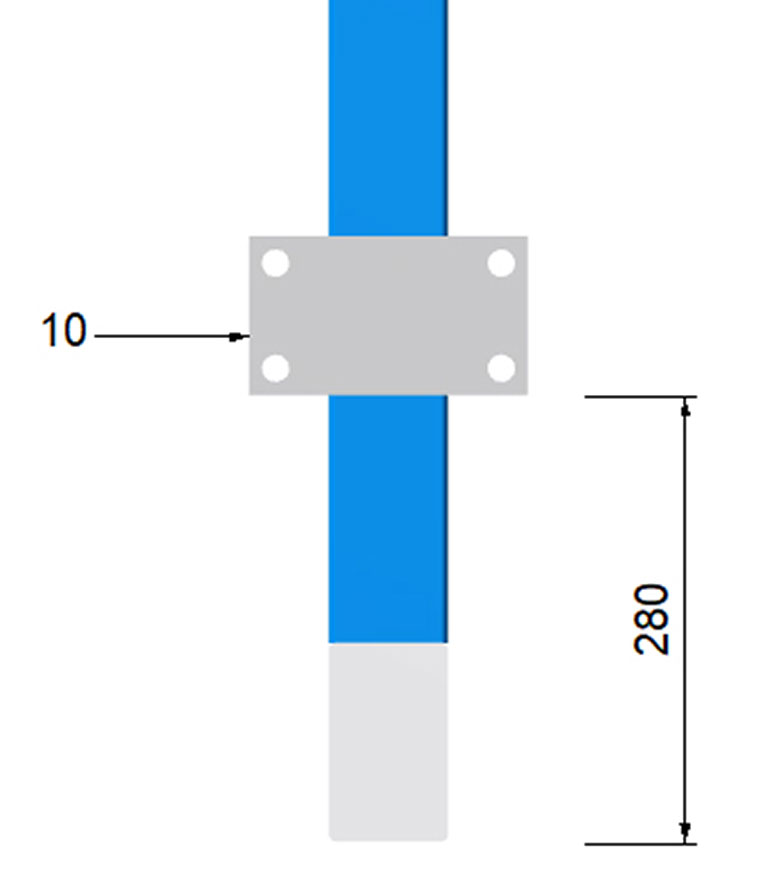

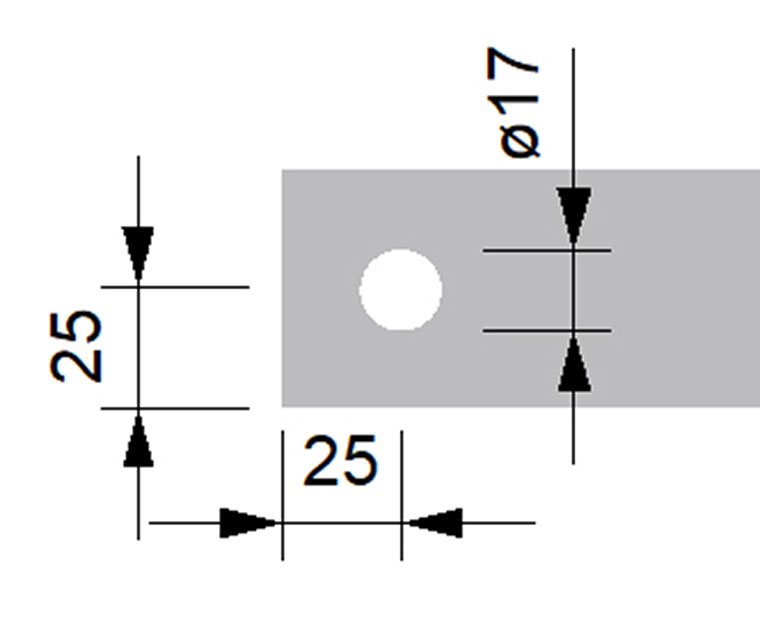

11. Drill a 17mm hole in both ends of item 6. Refer to diagram 6.

12. Clean any welds using a grinding disc or flap disc and paint as required.

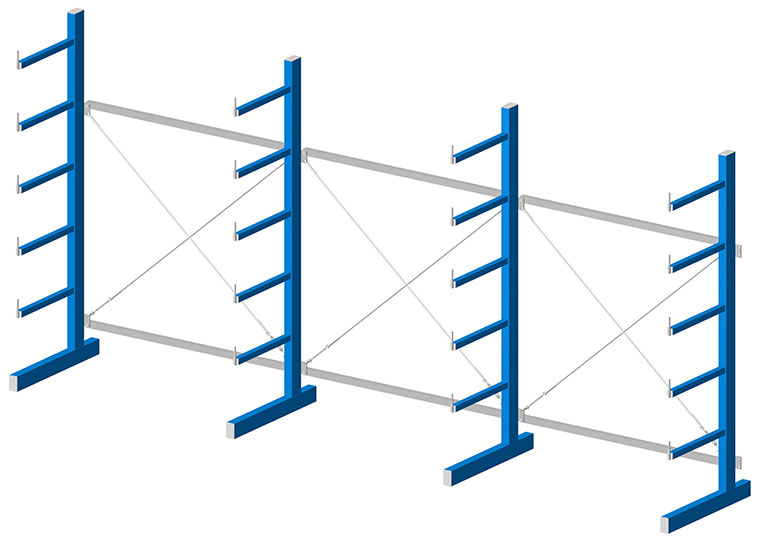

13. To assemble, you will need 2 people to help with the operation. Stand one of the post assemblies and using a bolt and nut, secure one of the angles to the lower hole in the lower plate and another angle to the top hole in the upper plate. Have another person hold the second post assembly in the appropriate position and secure the other ands of the angle using bolts and nuts. Secure the bolts and nuts tightly.

14. Cut the wire rope to the required length and attach it to the lower hole in the top plate using two wire rope clamps. A D shackle is used to secure a turnbuckle to the top hole in the lower plate of the second post assembly. Secure the loose end of the wire rope to the turnbuckle using two wire rope clamps. This needs to be repeated twice for each section so that there are two wire ropes running diagonally to each other.

15. Repeat the previous two steps for the remaining post assemblies.