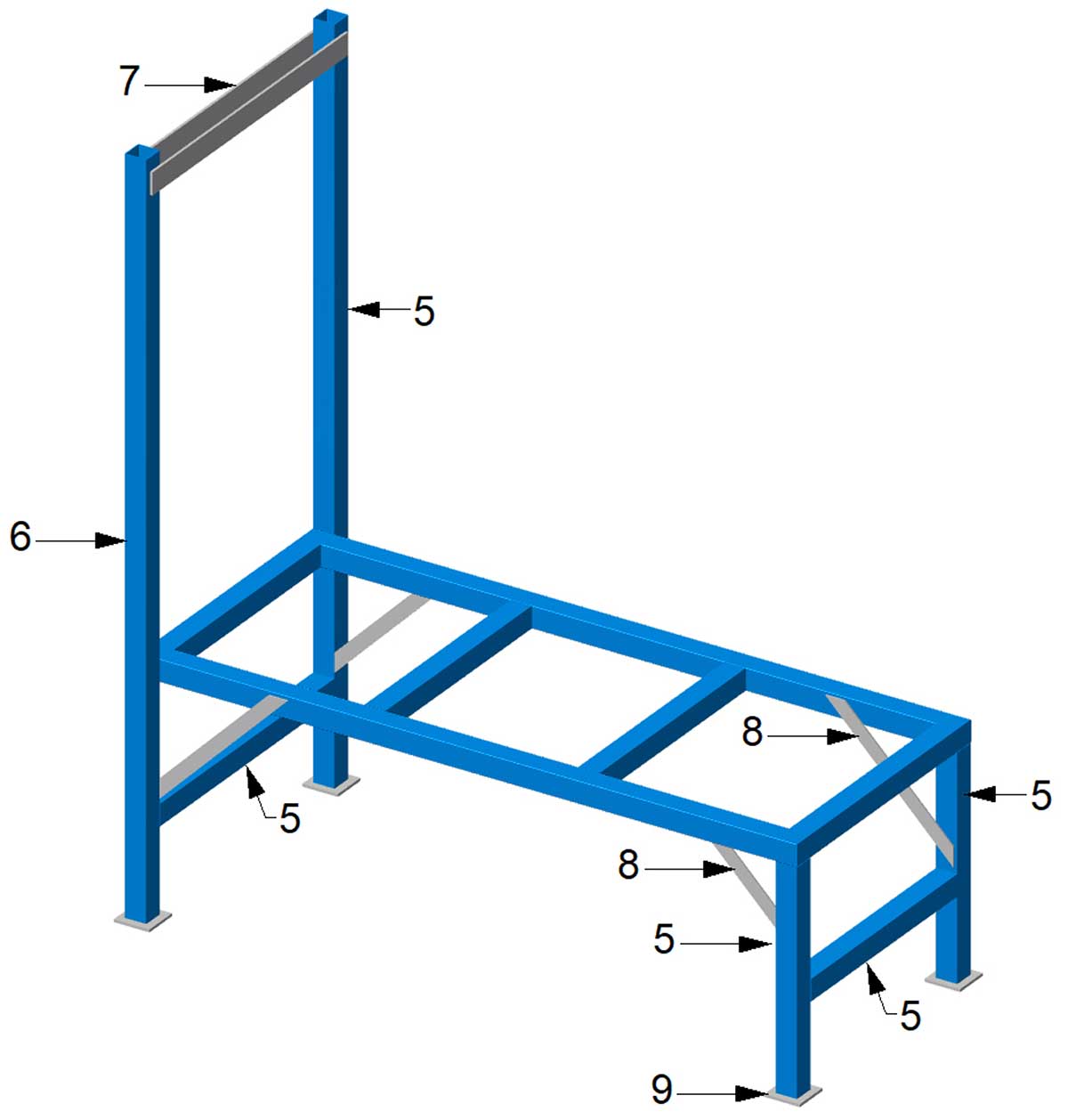

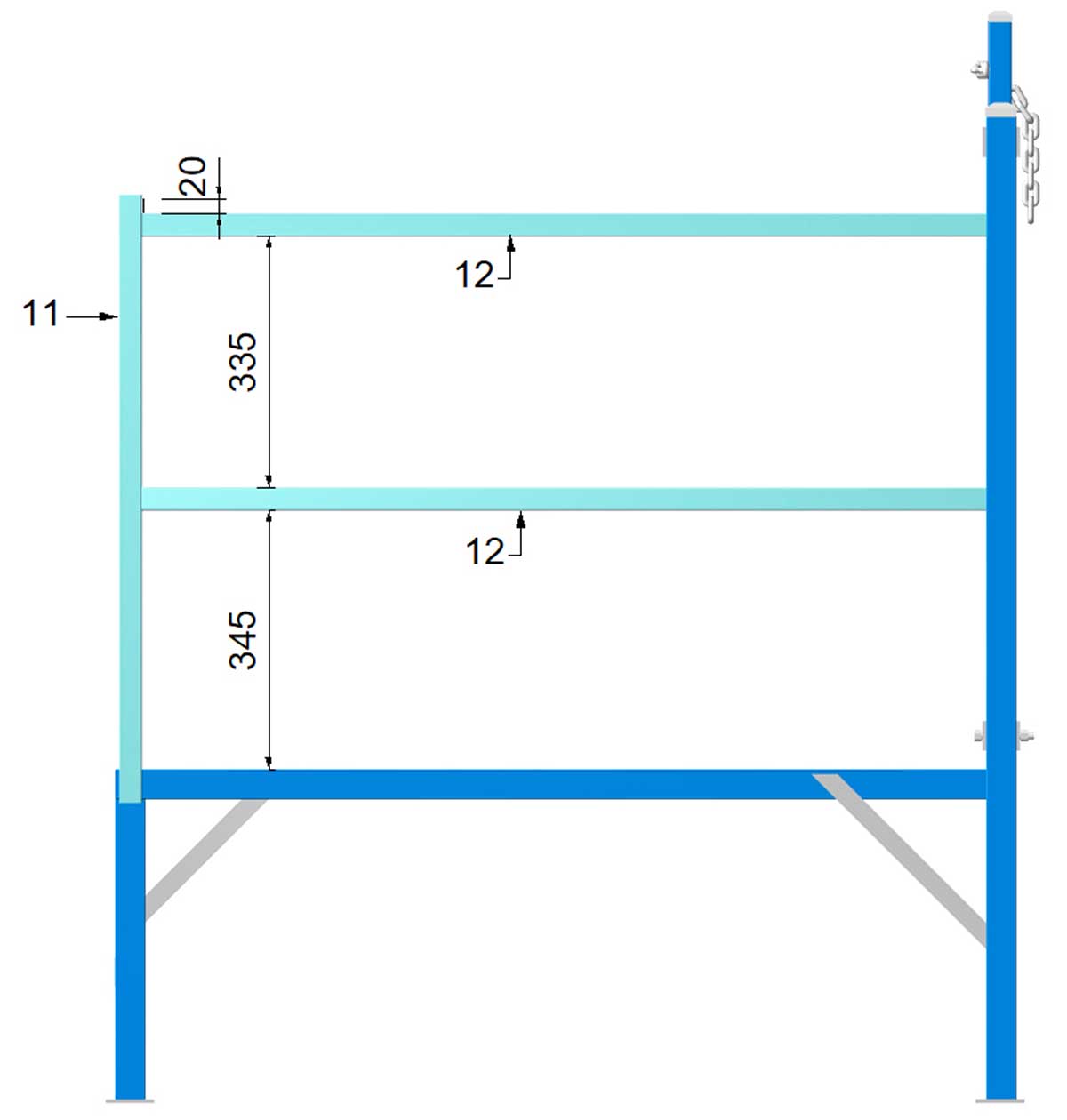

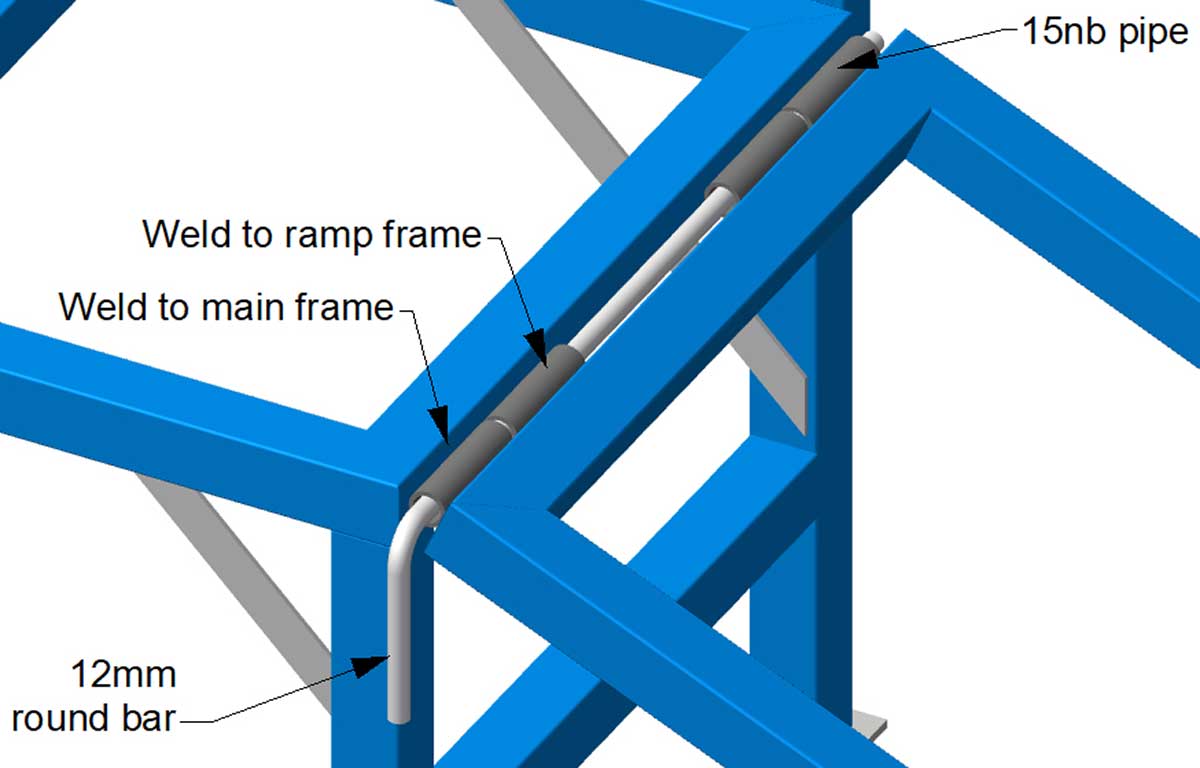

10. Cut four lengths of 15nb medium wall pipe each 75mm long. Cut one length of 12mm round bar 650mm long. Bend the round bar at a 90 degree angle 150mm in from the end.

11. Tack weld the 15nb pipe in place. The two outer lengths are welded to the main frame whilst the two inner lengths are welded to the ramp frame. Ensure that the tops of the frames are level with each other at the top and that the 12mm round bar will slide into the pieces of pipe, then fully weld the pipe in place. Refer to diagram 9.

12. Clean any welds using a grinding disc or flap disc and paint as required.

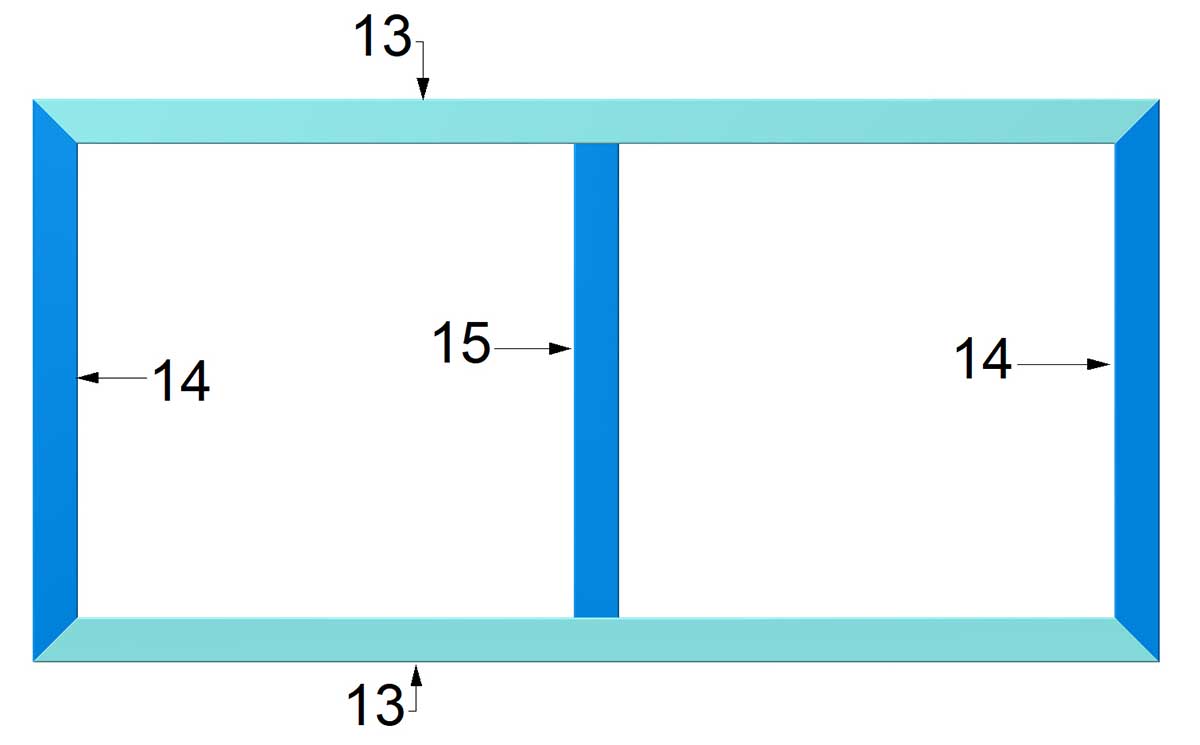

13. Install your choice of flooring. This can be exterior grade plywood, steel grating or expanded metal mesh.